Main applications of rotational molding products

date::2016-07-27 author: click:

With the continuous development of rotomolding molding technology, the types of rotomolding products are continuously increasing and the application range is also expanding. At present, the industries involved in rotomolding products at home and abroad include transportation, traffic safety facilities, entertainment industry, river channel dredging, construction, water treatment, medicine and food, electronics, chemical industry, aquaculture, textile printing and dyeing, etc.:

1, container type rotomolding parts

These plastic parts are widely used in storage and supply tanks, storage tanks, various industrial chemical storage and transportation containers, such as acids, alkalis, salts, chemical fertilizers, pesticide storage tanks, chemical companies, industrial coatings, rare earths The tanks, reaction tanks, turnover tanks, dustbins, septic tanks, domestic water tanks, etc. For example, rotomolded cross-linked polyethylene barrels made from Philip's rotomolded grade cross-linked polyethylene resin “Maricxcl-100” can be compared with metal barrels, and it has good chemical resistance and low maintenance costs. .

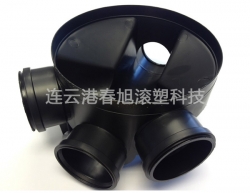

2.Rotor molding products for vehicles

Mainly uses polyethylene and polyvinyl chloride paste resin to rotomould all kinds of automotive parts such as air conditioning elbows, vortex tubes, backrests, armrests, fuel tanks, fenders, door frames and gear shift covers, battery housings, snowmobiles And motorcycle fuel tanks, aircraft fuel tanks, yachts and their water tanks, boats and buffer shock absorbers between the ship and the dock.

3, sports equipment, toys, crafts rotomolding parts

Mainly there are various parts made of polyvinyl chloride paste, such as water polo, floats, small swimming pools, recreational boats and their water tanks, bicycle seats, rotomolding pallets, surfboards and so on. As the rotomoulding mould can be manufactured by precision pouring, electroforming, etc.; the surface of the rotomoulded part has a good effect on the "replication" of the fine structure of the mould cavity surface, so the rotomoulding method can be used to make the products quite exquisite and beautiful. To produce products with great ornamental value, especially toys such as ponies, dolls, toy sand boxes, fashion models, and handicrafts.

4, all kinds of large or non-standard type rotomolding parts

Rotomolding products are also used in many types of boxes, shells, large pipes and other parts, such as shelves, machine housings, protective covers, lampshades, agricultural sprayers, furniture, canoes, camping vehicle canopies, playgrounds Installations, planters, bathrooms, toilets, telephone booths, advertising display boards, chairs, highway isolation piers, traffic cones, buoys, rivers and seas buoys, and construction barriers.

tags:Plastictankmanufacturers

Related Products:

related news:

- Popular new trends - plastic furniture abroad popular

- Warmly welcome relevant leaders to visit and guide the company

- Twenty-five years of grinding, domestic full rotomolding cars are expected to enter ten million homes

- Vertical flat bottom plastic tank product performance

- What are the transport advantages of plastic pallets?

- What are the advantages and features of plastic trays?

- The advantages of plastic trash cleaning, you make it?

- The trend of rotomolding plastic tanks

- The status of plastic trays in China

- Plastic tray manufacturers may be able to use the transformation to ease the pressure of overcapacity