The trend of rotomolding plastic tanks

date::2016-08-04 author: click:

In recent years, China's rotomoulding industry has continued to develop, but there are still problems. Due to the continued popularity of plastic storage tanks, problems that exist in the plastic tank rotomoulding industry should be emphatically put forward, and then the rotomoulding should be clearly defined for related issues. The future development trend of industry. Below we will give a detailed explanation on the specific issues and development direction.

(1) The scale of rotomoulding production enterprises is continuously expanding.

(2) By adjusting the product structure of rotomoulding products, the variety of rotomoulding products will increase, and the technological content of rotomoulding products will continue to provide high. The rotomolding products will develop in the direction of high performance and high added value.

(3) Increase research on related processes, equipment, and molds to form their own core technologies.

(4) Strengthen the development of special materials for rotomolding in China, and establish a raw material R&D center to completely change the current situation in which plastic materials mainly depend on imports.

At present, the rotomolding industry in foreign countries has developed rapidly, and due to various factors in China, the speed of rotomoulding and processing industry is lower than that of other plastics forming and processing industries. Recently, with the increasing understanding of the advantages of rotomolding, the rotomolding industry has seen an accelerated development in the country.

Rotomolding plastic tank technology

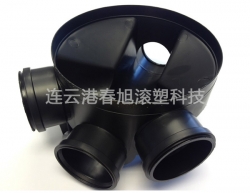

(1) Rotational plastic tanks are molded by rotomolding process.

(2) The company's PE plastic tanks are made of rotational molding materials—linear low-density polyethylene (LLDPE) or linear medium-density polyethylene (LMDPE). PE plastic tanks can contain inorganic acids, alkalis, salts, and many organic substances at room temperature.

(3) The minimum softening point of plastics used in rotational plastics storage tanks is 108°C and the maximum breaking point is -70°C, so it can generally be used to hold liquids at temperatures from -40°C to 60°C. If the weight of the loaded liquid is heavy or the temperature is higher than 60°C, a steel-lined plastic anticorrosive storage tank should be used to prevent the tank from being softened and deformed. If PE plastic tanks are used for chemical reactions or dilutions, corresponding tests should be done in advance to determine the reaction or dilution maximum temperature.

In recent years, with the development of various environmental protection projects, the demand for various types of storage tanks has greatly increased, and the market for rotomolding plastic tanks has been criticized by the industry. “Our rotomolded plastic PE tanks have irreplaceable advantages in the same type of products!”. As companies of all sizes have risen and the competition has become increasingly fierce and cruel, where does he come from?

Due to people's awareness and market regulation, people's ability to evaluate the price of rotomolding plastic tanks is still very weak, resulting in many customers buying at a high price or because of price prohibitive, so be sure to do Ready to work. Although it is a new thing, the rotomolding plastic storage tank will occupy the future market with its superior performance and reasonable price, and become the new darling of the rotomolding plastic storage tank industry.

tags:Plastictankmanufacturers

Related Products:

related news:

- The status of plastic trays in China

- Plastic Rotary Molding Process

- Twenty-five years of grinding, domestic full rotomolding cars are expected to enter ten million homes

- What are the transport advantages of plastic pallets?

- What are the advantages and features of plastic trays?

- The advantages of plastic trash cleaning, you make it?

- Plastic tray manufacturers may be able to use the transformation to ease the pressure of overcapacity

- Warmly welcome relevant leaders to visit and guide the company

- Popular new trends - plastic furniture abroad popular

- Vertical flat bottom plastic tank product performance