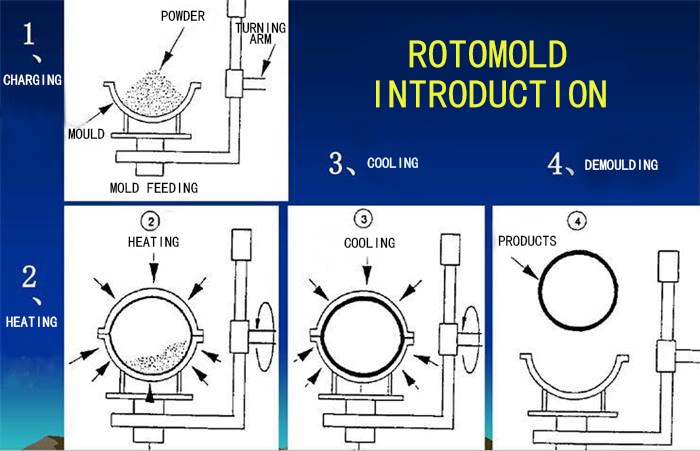

Rotational molding technology:

Rotational molding is also called Rotational Moulding. It is a quantitative powdery resin that is loaded into a cold mold. The rotomoulding machine drives the mold around two mutually perpendicular axes for slow revolution and rotation. The external heating source is used to heat the mold so that the resin powder is melted and evenly coated on the surface of the cavity of the entire mold by its own gravity, and finally, a method of obtaining a hollow product after being cooled and demolded.

Rotational process features:

1, Low cost rotomolding mold: the size of products of the same specifications, the cost of rotomolding mold is about 1/3 to 1/4 of the cost of blow molding, injection mold;

2. The edge strength of rotomolding products is good, and rotomoulding can achieve the thickness of the product edge more than 5 millimeters, completely solving the problem of thinner edges of hollow products.

3, Rotomolding can install a variety of inserts.

4, The shape of the rotomolding product can be very complex, and the thickness exceeds 5 mm.

5, Rotomolding can produce fully enclosed products.

6, Rotomolding products can be filled with foam material to achieve insulation.

7, Without the need to adjust the mold, the rotational wall thickness of the product can be adjusted freely (2mm above).

8, The product is hollow and seamless, but can adjust the wall thickness, so that the product has high strength.

9, Can provide a variety of surface pattern processing, the production of a variety of color products, can be used for anti-ultraviolet radiation aging treatment, for a variety of stone, wood simulation effect.

The main application of rotomolding products:

With the continuous development of rotomolding molding technology, the types of rotomolding products are continuously increasing and the application range is also expanding. At present, the industries involved in rotomolding products at home and abroad include transportation, traffic safety facilities, entertainment industry, river channel dredging, construction, water treatment, pharmaceuticals, food, electronics, chemical industry, aquaculture, textile printing and dyeing, etc.:

1, Container type rotomolding parts

These plastic parts are widely used in storage and supply tanks, storage tanks, various industrial chemical storage and transportation containers, such as acids, alkalis, salts, chemical fertilizers, pesticide storage tanks, chemical companies, industrial coatings, rare earths The tanks, reaction tanks, turnover tanks, dustbins, septic tanks, domestic water tanks, etc. For example, rotomolded cross-linked polyethylene barrels made from Philip's rotomolded grade cross-linked polyethylene resin “Maricxcl-100” can be compared with metal barrels, and it has good chemical resistance and low maintenance costs.

2.Rotor molding products for vehicles

Mainly uses polyethylene and polyvinyl chloride paste resins to rotomulate various automotive parts such as air conditioning elbows, vortex tubes, backrests, armrests, fuel tanks, fenders, door frames and gear shift covers, battery housings, snowmobiles And motorcycle fuel tanks, aircraft fuel tanks, yachts and their water tanks, boats and buffer shock absorbers between the ship and the dock.

3, Sports equipment, toys, crafts, rotomolding parts

Mainly there are various parts made of polyvinyl chloride paste, such as water polo, floats, small swimming pools, recreational boats and water tanks, bicycle seats, rotomolding pallets, surfboards and so on. As the rotomoulding mould can be manufactured by precision pouring, electroforming, etc.; the surface of the rotomoulded part has a good effect on the "replication" of the fine structure of the mould cavity surface, so the rotomoulding method can be used to make the products quite exquisite and beautiful. To produce products with great ornamental value, especially toys such as ponies, dolls, toy sand boxes, fashion models, and handicrafts.

4, All kinds of large or non-standard type rotomolding products

Rotomolding products are also used in many types of boxes, shells, large pipes and other parts, such as shelves, machine housings, protective covers, lampshades, agricultural sprayers, furniture, canoes, camping vehicle canopies, playgrounds Plants, planters, bathrooms, toilets, telephone booths, advertising display boards, chairs, highway isolation piers, traffic cones, buoys, rivers and seas buoys, and construction barriers.

Our company has custom-made all kinds of rotomolding molds and rotomolding products for customers at home and abroad for a long time. We can design molds according to the drawings or samples provided by customers and envisage designs. We can process various rotomoulded products for customers.