Twenty-five years of grinding, domestic full rotomolding cars are expected to enter ten million homes

date::2016-08-02 author: click:

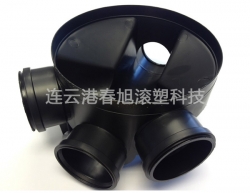

As an alternative to injection molding, blow molding, and extrusion molding, rotational molding has unique advantages in producing large-scale and super-large plastic products. Large hollow plastic products have the advantages of light weight, good impact strength, good corrosion resistance, recyclability, strong plasticity, and large volume. With the continuous development of the plastics industry and household appliances, automobiles, and aerospace industries, the application of large-sized hollow plastic products, such as missile packaging boxes and new energy vehicles, has become increasingly widespread.

The United Kingdom is recognized as the world leader in rotomolding and the UK has the world's largest rotomolding mold manufacturer, among which Boston Matthews Machinery Equipment Ltd is a leader in rotomolding technology. Compared with Britain and other developed countries in Europe and the United States, the start of rotomolding development in China will be later. However, after more than 20 years of development, it has become a mature process, and it has obvious advantages in distinguishing itself from other processes. At present, the modern production of large hollow plastic products and special plastic products has already been processed, and the application fields have been continuously expanded. The rotomoulding industry has made considerable progress. It should be said that the rotomoulding industry has formed a complete industrial chain of raw materials, equipment, molds and products.

In June 2010, China's first self-developed and researched ship was a sea-going ship with polyethylene. Instead of a single piece of wood and a steel plate, the polyethylene boat is formed once in the manufacturing process. There are no seams on the hull. Its service life is three times higher than that of ordinary wooden boats, and its high performance is twice that of fiberglass ships. China's large-scale product rotomolding technology reached the first peak.

Recently, China Chemical Industry News reported that a large-scale special-shaped plastic product rotomolding advanced manufacturing technology was jointly developed by Beihua British Blue Laboratory, Ningbo Greentech New Materials Technology Co., Ltd. and Wenling Xuri Rotary Technology Co., Ltd. Plastic body provides technical foundation.

The rotomoulding industry, as a rising industry in the ascendant, has shown a momentum of vigorous development. In the near future, full-rotation vehicles using advanced technology and integrated production are expected to enter millions of households.

tags:Plastictankmanufacturers

Related Products:

related news:

- The status of plastic trays in China

- The trend of rotomolding plastic tanks

- Warmly welcome relevant leaders to visit and guide the company

- What are the transport advantages of plastic pallets?

- Vertical flat bottom plastic tank product performance

- Popular new trends - plastic furniture abroad popular

- Plastic tray manufacturers may be able to use the transformation to ease the pressure of overcapacity

- The advantages of plastic trash cleaning, you make it?

- What are the advantages and features of plastic trays?

- Plastic Rotary Molding Process