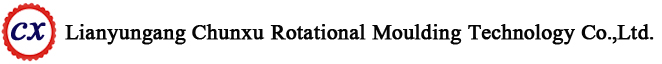

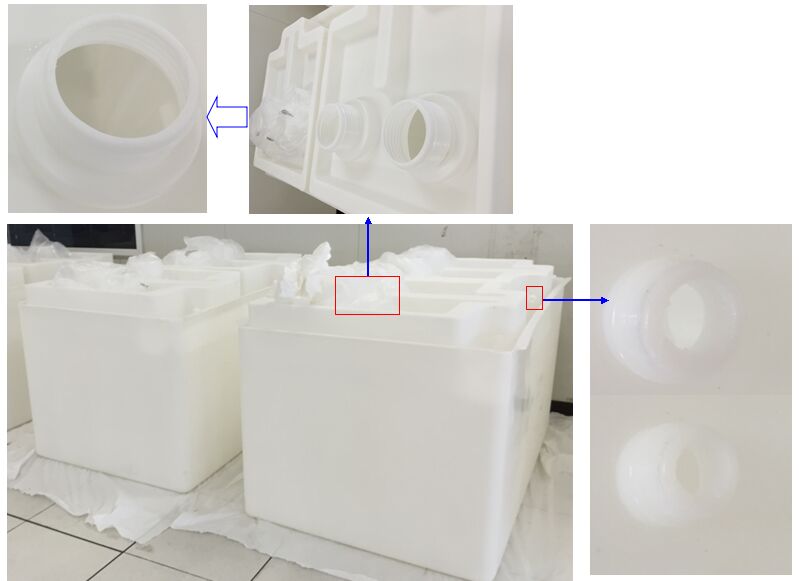

Solar storage container

Rotomoulding solar energy storage tank product features:

Mold cost savings

Rotary forming is a low-pressure process, and the mold is mainly a thin hollow shell that defines the external shape and the surface of the component. This leads to a much lower mold cost than other processes

Uniform wall thicknessUniform wall thicknesses can be maintained within ±20%, providing tighter tolerances than rotary molding for blow molding. Rotary forming tends to produce an increased wall thickness at the outer corner, which increases the strength of the part. Compared to blow molding or thermoforming, it tends to produce a thin outer corner. Wall thickness can range from 1/32 to 1 inch (0.8mm to 25mm).

Corrosion resistance

Plastics do not corrode and can be designed to adapt to many climatic conditions.

Anti-UV

The resin contains additives that prevent failure due to exposure to ultraviolet light.

Chemical resistance

Typical rotary molding resins have excellent resistance to various chemicals, making them ideal materials for packaging, storage and chemical contact.

Intensity

Plastic parts can be designed with impact and anti-sag material. Parts can strengthen the molding features and increase strength.

Economy

Plastics are lighter, and better fuel economy and manufacturing costs are less expensive than metal parts.

A large number of assembled components can be incorporated into a single plastic component. This not only eliminates assembly time and costs, but also brings more functional parts with better ergonomics and styling.

Aesthetics

Since the color is part of the molded part, no secondary painting operation is required. The result: your parts can use uniform, maintenance-free and cost-effective colors.

Graphics can be made according to your specifications and molded into parts, protecting the graphics from falling off.

Design flexibility offers the opportunity to enhance cosmetics and styling.

相关标签:Plastictankmanufacturers

下一篇:Rotational display box

Quality assurance

Quality assurance Quick delivery

Quick delivery Professional custom

Professional custom